Parameter Characteristic Application Videos

Product Introduction

Gas flow controller MC11-EA7000C, suitable for equipment such as wave soldering, reflow soldering, and atmosphere protection furnaces that require the introduction of protective gas. The controller needs to be used in conjunction with an oxygen analyzer. The gas flow controller controls the valve size based on the oxygen concentration collected by the oxygen analyzer. When the oxygen concentration in the environment is high, the proportion of valves is large; Low oxygen concentration (meets the set requirements), small valve ratio or closed. Automatically control the oxygen concentration inside the atmosphere protection furnace without manual intervention, saving nitrogen and effectively reducing the operating costs of equipment such as the atmosphere protection furnace.

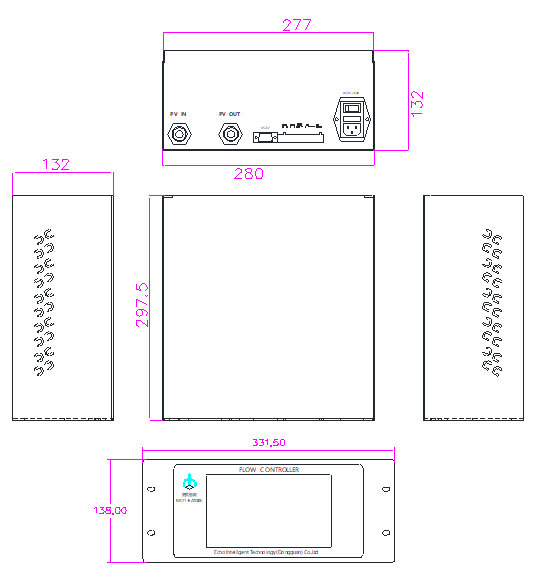

Product dimension diagram

Technical Parameter

Control principle | PID |

Display mode | 7-inch touch screen |

detection range | 0-25% O2 |

Measurement accuracy | ±30ppm |

control cycle | 0.1~100S |

Input Interface | Non-Isolated4~20mA/0-10V DC |

| One channel switch input |

control output | 1-channel programmable relay alarm output (maximum load 5A) |

Communication mode | RS232,RS485 |

Working power supply | AC85~264V 50/60Hz |

Environmental temperature and humidity | -5℃~+50℃,<80% RH |

Mpa | 0.4-0.6MPa |

Flow range | 0~65m3/h |

Traffic statistics | Includes instantaneous flow and cumulative flow display |

Gas path protection | Bypass Protection |

Specification and size | 138mm×332mm×335mm(H×W×D) |

Dimension | 134mm×232mm(H×W) |

Gas interface | G1/2internal thread,Default connection:10mmQuickly plug in |

Installation method | Placed or embedded |

Product Features

1. The instrument adopts a 7-inch touch screen display, which is easy to operate and has clear display;

2. The instrument is equipped with RS-232, RS485 communication ports and analog input;

3. It has self-tuning function and PID control parameter setting;

4. Signal input diversity, capable of analog input signals, as well as RS485 or RS232 input;

5. High control accuracy, small fluctuations, and significant nitrogen saving effect;

6. Built in bypass protection ensures that there is always nitrogen input into the furnace, protecting against unnecessary losses caused by proportional valve failure;

7. Built in flow sensor with instantaneous and cumulative flow display functions.

English

English Chinese

Chinese